What Are Hydraulic Hoses?

Hydraulic hose is used to complete the connection and convey hydraulic fluid under pressure between components within a hydraulic system. They generally consist of rubber or elastomeric material reinforced with multiple layers of metal or textile and are covered with an outer layer of protective material. These are designed to give them the durability needed to withstand the pressures to which they are often subjected and the flexibility to fit into tight or confined spaces all while properly containing the fluid.

These components come in a variety of sizes and materials to suit the requirements and restrictions of a wide range of applications. They are also available with different fitting connector ends to accommodate different hydraulic systems.

Below we provide an overview of hydraulic hoses, outlining their functions, applications, types available, and the products available at Jason Industrial.

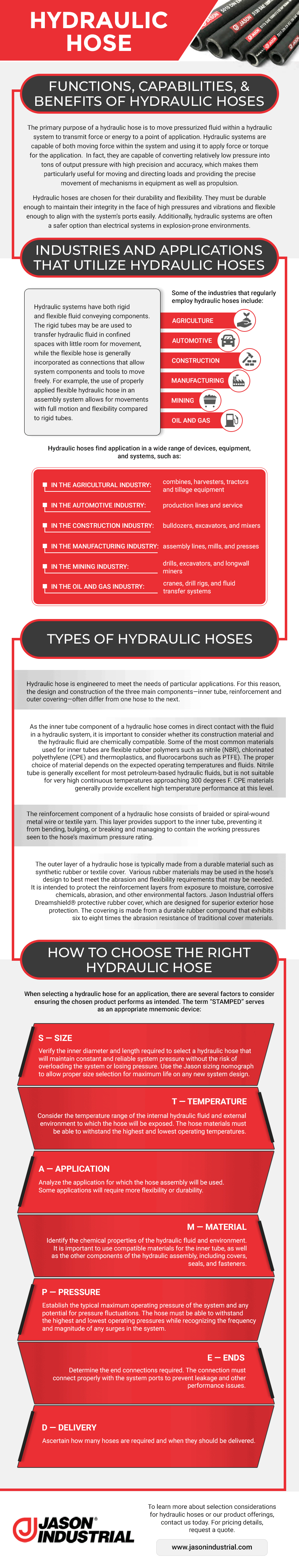

Functions, Capabilities, & Benefits of Hydraulic Hoses

(Click to Expand)

Hydraulic hoses are chosen for their durability and flexibility. They must be durable enough to maintain their integrity in the face of high pressures and vibrations and flexible enough to align with the system’s ports easily. Additionally, hydraulic systems are often a safer option than electrical systems in explosion-prone environments.

Industries and Applications That Utilize Hydraulic Hoses

Hydraulic systems have both rigid and flexible fluid conveying components. The rigid tubes may be are used to transfer hydraulic fluid in confined spaces with little room for movement, while the flexible hose is generally incorporated as connections that allow system components and tools to move freely. For example, the use of properly applied flexible hydraulic hose in an assembly system allows for movements with full motion and flexibility compared to rigid tubes.

Some of the industries that regularly employ hydraulic hoses include:

- Agriculture

- Automotive

- Construction

- Manufacturing

- Mining

- Oil and gas

Hydraulic hoses find application in a wide range of devices, equipment, and systems, such as:

- In the agricultural industry: combines, harvesters, tractors, and tillage equipment

- In the automotive industry: production lines and service

- In the construction industry: bulldozers, excavators, and mixers

- In the manufacturing industry: assembly lines, mills, and presses

- In the mining industry: drills, excavators, and longwall miners

- In the oil and gas industry: cranes, drill rigs, and fluid transfer systems

Types of Hydraulic Hoses

Hydraulic hose is engineered to meet the needs of particular applications. For this reason, the design and construction of the three main components—inner tube, reinforcement and outer covering—often differ from one hose to the next.

As the inner tube component of a hydraulic hose comes in direct contact with the fluid in a hydraulic system, it is important to consider whether its construction material and the hydraulic fluid are chemically compatible. Some of the most common materials used for inner tubes are flexible rubber polymers such as nitrile (NBR), chlorinated polyethylene (CPE) and thermoplastics, and fluorocarbons such as PTFE). The proper choice of material depends on the expected operating temperatures and fluids. Nitrile tube is generally excellent for most petroleum-based hydraulic fluids, but is not suitable for very high continuous temperatures approaching 300 degrees F. CPE materials generally provide excellent high temperature performance at this level.

The reinforcement component of a hydraulic hose consists of braided or spiral-wound metal wire or textile yarn. This layer provides support to the inner tube, preventing it from bending, bulging, or breaking and managing to contain the working pressures seen to the hose’s maximum pressure rating.

The outer layer of a hydraulic hose is typically made from a durable material such as synthetic rubber or textile cover. Various rubber materials may be used in the hose’s design to best meet the abrasion and flexibility requirements that may be needed. It is intended to protect the reinforcement layers from exposure to moisture, corrosive chemicals, abrasion, and other environmental factors. Jason Industrial offers Dreamshield® protective rubber cover, which are designed for superior exterior hose protection. The covering is made from a durable rubber compound that exhibits six to eight times the abrasion resistance of traditional cover materials.

Hydraulic Hose Products From Jason Industrial

At Jason Industrial, we offer a broad selection of hydraulic hose, coupling, and crimping equipment and accessory products suitable for use in the industrial sector. See the catalog for details and descriptions.

Our hydraulic hose offerings include:

- Series 5011 (SAE 100R1/1SN smooth finish cover)

- Series 5012 (SAE 100R1/1SN wrap finish Dreamshield® cover)

- Series 5021 (SAE 100R2/2SN smooth finish cover)

- Series 5022 (SAE 100R2/2SN wrap finish Dreamshield® cover)

- Series 5040 (SAE 100R4 Extra Flexible)

- Series 5050 (SAE 100R5 Hi-temp w/black textile cover)

- Series 5161 (SAE 100R16/2SC smooth finish cover)

- Series 5162 (SAE 100R16/2SC wrap finish Dreamshield® cover)

- Series 5171 (SAE 100R17 smooth finish cover)

- Series 5172 (SAE 100R17 wrap finish Dreamshield® cover)

- Series 5192 (SAE 100R19 wrap finish Dreamshield® cover)

- Series 5122 (SAE 100R12 wrap finish Dreamshield® cover)

- Series 5132 (SAE 100R13 wrap finish Dreamshield® cover)

- Series 5152 (SAE 100R15 wrap finish Dreamshield® cover)

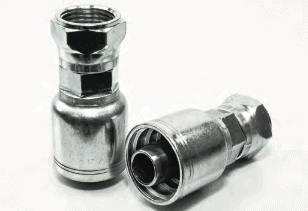

The hose couplings we offer include:

- 12 Series (for Jason wire braid hoses and 5040)

- 40 Series (for use with 5122)

- 60 Series (for use with 5132 and 5152)

- 75 Series (field attachable couplings for use with 5050)

We also provide a variety of crimping equipment, from small portable units to large-scale production crimpers:

- Series JCD100S-T420 (portable service hose crimper)

- Series JCD165M-T420 (standard hose crimper)

- Series JCD205-WB (hydraulic hose crimper)

- Series JCC-200 (general production hose crimper)

- JIC340 (general production hose crimper w/controller)

- Other crimpers and assembly equipment are available

How to Choose the Right Hydraulic Hose

When selecting a hydraulic hose for an application, there are several factors to consider ensuring the chosen product performs as intended. The term “STAMPED” serves as an appropriate mnemonic device:

- S — Size: Verify the inner diameter and length required to select a hydraulic hose that will maintain constant and reliable system pressure without the risk of overloading the system or losing pressure. Use the Jason sizing nomograph to allow proper size selection for maximum life on any new system design.

- T — Temperature: Consider the temperature range of the internal hydraulic fluid and external environment to which the hose will be exposed. The hose materials must be able to withstand the highest and lowest operating temperatures.

- A — Application: Analyze the application for which the hose assembly will be used. Some applications will require more flexibility or durability.

- M — Material: Identify the chemical properties of the hydraulic fluid and environment. It is important to use compatible materials for the inner tube, as well as the other components of the hydraulic assembly, including covers, seals, and fasteners.

- P — Pressure: Establish the typical maximum operating pressure of the system and any potential for pressure fluctuations. The hose must be able to withstand the highest and lowest operating pressures while recognizing the frequency and magnitude of any surges in the system.

- E — Ends: Determine the end connections required. The connection must connect properly with the system ports to prevent leakage and other performance issues.

- D — Delivery: Ascertain how many hoses are required and when they should be delivered.

Contact the Hydraulic Hose Experts at Jason Industrial Today

Some industry professionals find determining which hydraulic hose is right for their system to be challenging. For these individuals, the team at Jason Industrial is here to help.

At Jason Industrial, we are an industry-leading supplier of high-quality industrial hose products. In addition to using the above method to assist customers in selecting the ideal hydraulic hose product for their needs, we offer the following tools:

- Nomographic charts: provides information about the relationship between a hose assembly’s inner diameter, flow capacity, and flow velocity

- The Jason MyCrimp App: give users up-to-date information regarding the use of hoses, couplings, and crimping equipment available at Jason Industrial

To learn more about selection considerations for hydraulic hoses or our product offerings, contact us today. For pricing details, request a quote. Want to be a Jason Industrial distributor? Read more here.